torsion test ductile failure|why do ductile materials fail : purchasing Torsion testing predicts a material’s behavior under twisting forces by assessing key properties such as torsional strength, shear modulus, yield strength in torsion, ductility, and brittleness. It enables the understanding of fatigue behavior, . Resultado da 15 de set. de 2023 · Category western. Language translated spanish. Parody the simpsons. Character bart simpson luann van houten. Artist tufos. Female anal. Date 2023-09-15 20:02 (5 months ago) Pages 16.

{plog:ftitle_list}

web14 de jun. de 2022 · Rhenata Schmidt, assistente de palco do Programa do Ratinho, além de empresária, jornalista e atriz, também é um verdadeiro sucesso nas redes sociais.No Instagram, onde soma mais de 901 mil seguidores, ela costuma compartilhar bastidores de seus trabalhos e registros de momentos de lazer, incluindo belíssimas fotos de biquíni.. .

If the primary failure method is shear failure, such as the case for most ductile materials, then this occurs when we look at the axis where $\theta = 0$, and the stress is entirely in shear. However, if we look at the axis where .

Torsion testing predicts a material’s behavior under twisting forces by assessing key properties such as torsional strength, shear modulus, yield strength in torsion, ductility, and brittleness. It enables the understanding of fatigue behavior, .If a material is ductile, failure is specified by the initiation of yielding. Maximum-shear-stress criterion (Tresca criterion) Typically, ductile materials fail by shear stress (slipping that occurs .Ductile failure is also known as plastic collapse, general yielding or ductile overload, and is the failure mode that occurs when a material is simply loaded to beyond its ultimate tensile .

Ductile failure: Maximum distortional energy theory von Mises proposed a different hypothesis: yielding occurs when the distortion energy density equals or exceeds the distortion energy .

Shear dominated states of loading are present in many industrial applications and typical impact processes. The paper gives a review of the well known methods for mea-suring the high strain . Ductile failure is still failure but a much more benign form of failure than is brittle failure. The present work gives quantitative measures for these states of ductile failure behaviour. Examples now follow. We present the specimen types and the stress–strain curves in compression, and we compare the material behavior in compression to that in tension. Also, we present the .

Mirone and Corallo have proposed a local viewpoint for evaluating the influence of the stress triaxiality and Lode angle on ductile failure, analyzing three theories, namely, the . Brittle failure, i.e., no shear stresses, occurs on a principal plane having maximum tensile stress at 45° to the wire axis. However, ductile torsion failure may also initiate on a plane parallel to the wire axis giving a helix fracture due to twisting torque of the torsion test. This is a ductile longitudinal delamination failure .

According to Mirone and Corallo , the phenomenon of ductile failure is influenced by the relation with the variables from the stress-strain characterization, and failure predictions are better described by plastic strain, stress . For example, if a smooth bar is used in a tensile test, C t θ = 0; if a torsion test is conducted, C s .

Why does a ductile rod in torsion fail at an angle perpendicular to its axis? I know the reason for brittle material failing in pure shear but I don't understand the reason for ductile material. . $\tau_{max}$ is reached before $\sigma_y$, .Torsion Only: Applying only torsional loads to the test specimen. Axial-Torsion: Applying both axial (tension or compression) and torsional forces to the test specimen. Failure Testing: Twisting the product, component, or specimen until failure. Failure can be classified as either a physical break or a kink/defect in the specimen. The main purpose of the test program was to design a set of experiments that as clearly as possible brings out the effects of stress triaxiality and the deviatoric stress state on ductile failure. The DNT specimens tested in the whole range of combined tension–torsion available provides a set of highly discriminating tests. 15. Expected failure for Mild Steel and Cast Iron Specimens and reasoning: Fracture in torsion for ductile materials generally occur in the plane of maximum shear stress perpendicular to the axis of bar where as for the brittle material failure occurs along 45° hilux to the axis of bar due to tensile stress across that plane.

Background Using a thin-walled tube torsion test to characterize a material’s shear response is a well-known technique; however, the thin walled specimen tends to buckle before reaching large shear deformation and failure. An alternative technique is the surface stress method (Nadai 1950; Wu et al. J Test Eval 20:396–402, 1992), which derives a shear .

why do ductile materials fail

Introduction To put meaning to the data and conclusions drawn in this experiment several things must be known about the materials tested and the theory behind torsion testing. The two materials tested, cast iron and mild steel, have opposing characteristics. Steel is classified as a ductile material, a ductile material is known to be able to experience very large .

Three simple experimental results including uniaxial tension test, pure torsion test and plane strain test are used to calculate parameters. Assume that b = 3 / 3, E = 2 and F = 1 / 2. For pure torsion test, η = 0 and ξ = 0. Taking the failure strain ε ¯ Tor of pure torsion into Eq. (22), we can get (31) A = 1 ε ¯ Tor b c For plane strain .The shaft shown in Figure 5 combines dominant bending with torsion, so the fracture is closer to 90 degrees. The fracture angle offers key evidence. If the angle of a fatigue failure is: Closer to 90 degrees, it is a dominant bending force. Midway between 45 degrees and 90 degrees, it is a combination of torsion and bending forces. In a torsion test the applied torque T is plotted versus the measured angle of twist . Various failure criteria have been developed to predict failure by yielding in ductile materials and failure by fracture in brittle materials. In the following we will briefly present the maximum normal stress fracture criterion, the maximum shear stress or .

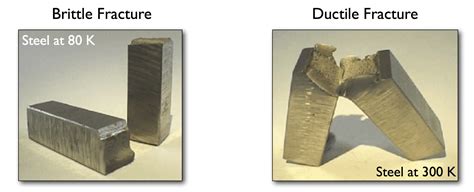

Clearly, the required energy in brittle failure is quite less than the ductile failure. Fig. 1: Brittle vs Ductile Fracture. Brittle Fracture Mechanism. The mechanism of brittle fracture shown above is known as Brittle cleavage fracture. This occurs in metals with a high strain-hardening rate and relatively low cleavage strength.

Background The damage and failure behavior of ductile metals depends on the stress state as well as on the loading history. Biaxial experiments with suitable specimens can be used to targeted generate different loading conditions, thus allowing the investigation of a wide variety of load cycles with different stress states. Objective In the biaxial experiments with the . Hence ductile materials failure occurs due to principle shear stress. In torsion test maximum shear stress is in the direction perpendicular to longitudinal axis. Hence, ductile failure plane is torsion will be perpendicular to longitudinal axis. Cast iron is a brittle material. So failure occurs as per case 5.The second row shows the images after torsion failure test, indicating the concentric abrasion mark and showing the fibrous dimples DISCUSSION The present study tried to evaluate the cyclic fatigue (in deionized water at body temperature), torsional failure, and flexural resistance of two reciprocating and two rotating files. Ductile failure occurs when a material is loaded beyond its yield strength and begins to plastically deform for a period before ultimately failing. Brittle materials experience little or no plastic deformation before breaking. .

• Torsion - introduction • Torsion test • Torsional Failure Modes • Plastic deformation • Dislocations – introduction • Edge Dislocation • Dislocation movements Dr. M. Medraj 2 • From observation, the angle of twist of the shaft is proportional to the applied torque and to the shaft length. L T ∝ ∝ φ φ Moreover the calibration of a ductile failure criterion is a time consuming process with a large number of parameters involved: for example the Gurson model . found a lower strain at failure in a torsion test (η = 0) than in a tensile test (η = 0.4) in various metals. These results were further confirmed by the work of Wierzbicki .330 Mech Time-Depend Mater (2011) 15:327–340 Fig. 3 Different failure modes for torsion tests Fig. 4 Computed stress–strain curves with different gauge lengths occur during the test and that relatively high deformations without necking or buckling are

118 MODULE 5. MATERIAL FAILURE (a) test y y E 1 (b) Ductile (c) Brittle Figure 5.1: Uni-axial stress-strain response for ductile and brittle materials. The basic question in this case is: For general stress states (e.g. solutions to 2D or 3D elasticity problems), for what combinations and intensities of stress components will theaxis. Brittle failure, i.e., no shear stresses, occurs on a principal plane having maximum tensile stress at 45 to the wire axis. However, ductile torsion failure may also initiate on a plane parallel to the wire axis giving a helix fracture due to twisting torque of the torsion test. This is a ductile longitudinal delamination failure [2]. The plastic deformation and failure of Al-6061-T6 tubes under radial paths of tension and torsion was investigated experimentally using a custom specimen design and test set-up. The set-up involves a 2-inch diameter (50 mm) tube with a 0.125-inch (3.2 mm) wall into which a test section approximately 0.6-inch wide (15 mm) and a wall thickness of .In a torsion test, a test specimen is twisted to a specified angle with a predetermined force, or until failure occurs. Torsion testing is used to examine how a material or test sample behaves when twisted or subjected to torsional stresses as a consequence of applied moments that create shear stress along the axis. . Ductile vs. Brittle .

TENTION TORSION 0 b. Briefly explain the maximum shear stress theory for ductile failure, e.g. A36 steel; and the maximum normal stress theory for brittle failure, e.g. cast iron. Refer to your CE215 textbook. The Maximum Shear Stress theory states that failure occurs when the maximum shear stress from a combination of principal stresses equals or exceeds . Torsion testing of basic grade mild steel with an axial torsional testing equipment is one type of test used to assess the torsional characteristics of the structural material.The Ganjiani ductile failure model [10] beside Lou’s model [21] were employed to predict the ductile failure of CuZn30 brass. Despite their different mathematical formulations, both the Ganjiani and Lou models were selected which seems to have similar predicted results. . In the torsion test, failure initiates at the outer radius of the . Equation (2.1) is the form for the D/B transition, clear, simple and above all else, rigorous. Please see [] for the derivation of (2.1)The materials type is specified by the T/C ratio, and any stress state of concern is embedded in the dilatational failure stress term in (2.1). A concise statement of the complete failure theory is given in [].The failure theory in general .

torsion test examples pdf

O Outro Lado do Paraíso - Capítulo de quinta-feira, 16/11/2017, na íntegra. Renato é chamado às pressas no hospital e Gael implora para que ele salve Clara. Lívia se preocupa com o bebê e segue a enfermeira até o berçário. Lívia não deixa Clara segurar o filho. Clara e Gael aceitam a sugestão de nome que Sophia dá para o bebê, Tomaz.

torsion test ductile failure|why do ductile materials fail